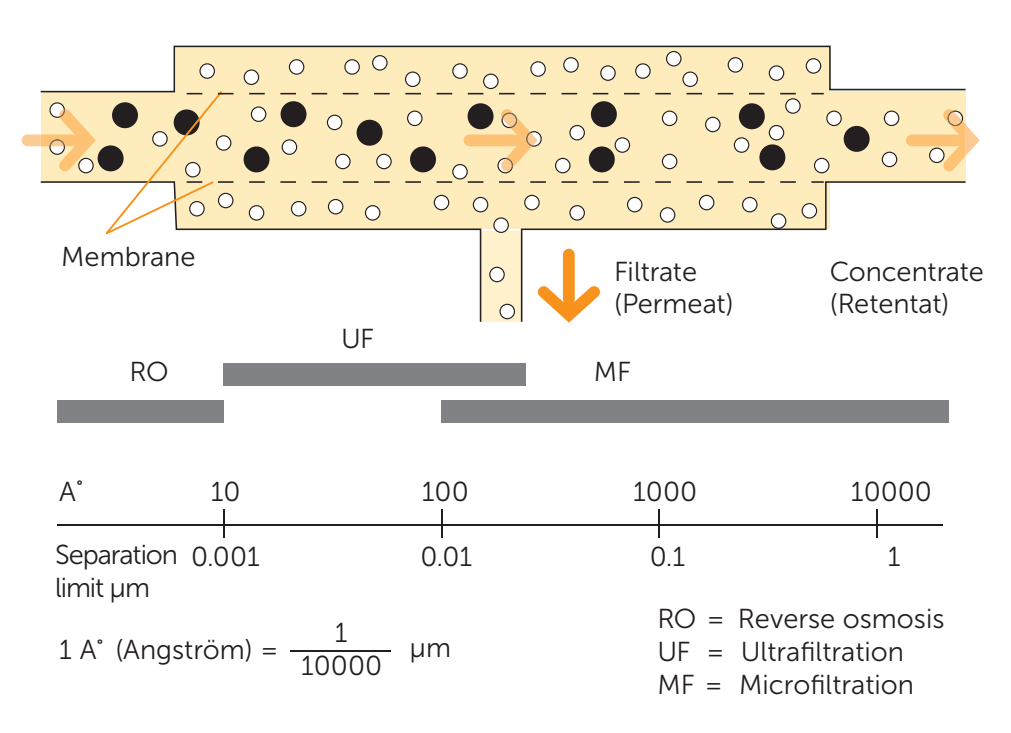

Crossflow filtration is a method for filtering liquids which is used in the beverage industry, the foodstuffs industry, the pharmaceutical and bio-industry and in the field of environmental protection when it comes to the filtration or diafiltration of suspensions. Static crossflow filtration as well as dynamic crossflow filtration (rotation filtration) each have their specific advantages. Please contact us for your application.

In contrast to dynamic crossflow filtration, static crossflow filtration involves a tangential flow over the filter surface.

This also creates a turbulent flow on the membrane surface. The shear forces during the overflow of the membrane surface prevent the separated material from forming a coating (cake) on the filter surface. The surface is cleaned in the process so that the flow rate remains as constant as possible.

In addition to the product properties (density, viscosity, solids content) and ingredients, the flux rate is primarily determined by the filter layer pore size, the product temperature, the differential pressure and the circulation speed. In the case of preferential recirculation filtration via a receiver tank, the concentration of the retained solids (retentate) increases on the unfiltrate side. The permeate is fed into a sterile or hygienic filtrate tank by means of the system pressure.

Filtration base

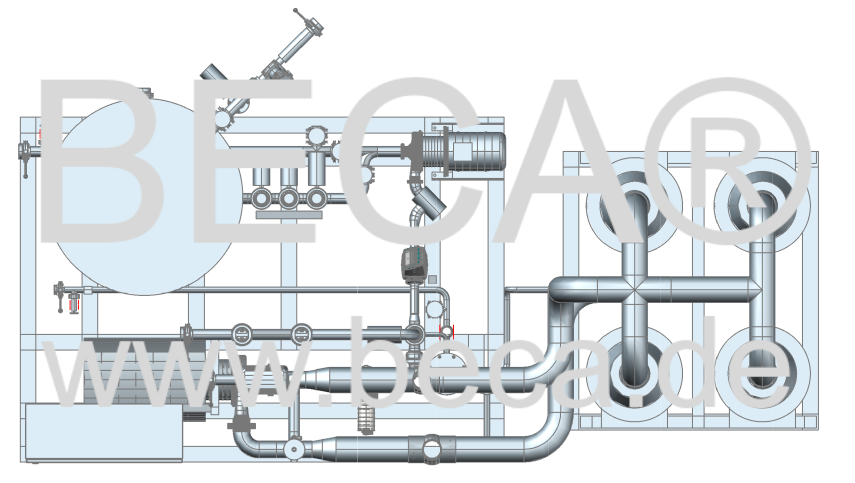

By means of a circulation pump, the medium to be filtered is passed over the membrane (ceramic, hollow fibre, etc.), while a booster pump generates the required filtration pressure in the membrane. The unfiltered product is fed into the circuit in proportion to the permeate rate. The retentate is continuously discharged into the receiver tank. As a result, the proportion of solids and colloids in the receiver tank increases continuously. The cyclical backwashing with permeate prevents blocking of the membrane and maintains the flux rate.

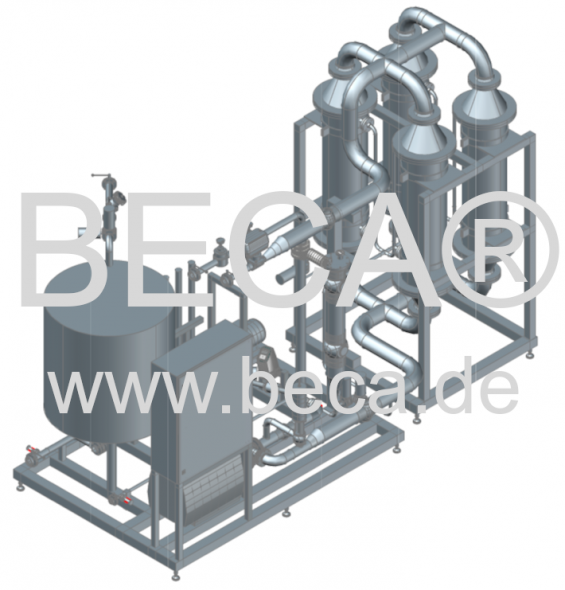

High-quality yet cost-effective cross-flow filtration in a continuous or batch process.

Use of various membrane materials (ceramic, hollow fibre, ...), optimised to your needs.

Modular skid design, expandable. Optionally, each membrane can be switched on or off separately.

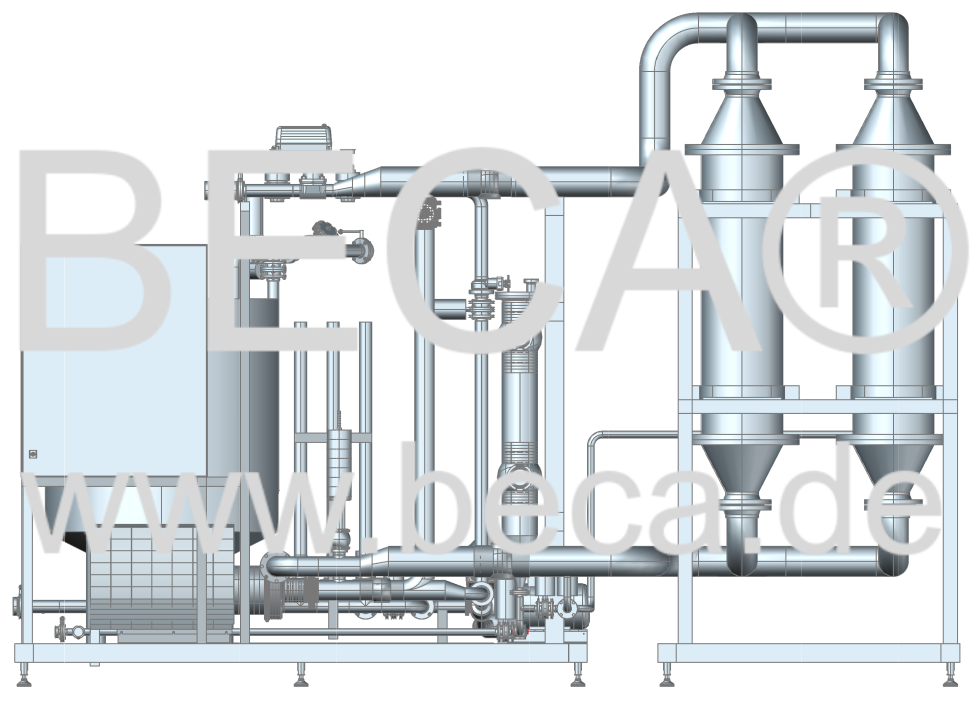

Optional reverse flow. Reversal of flow direction for longer filtration life.

Reduced and optimised energy consumption through series connection and circuit combinations.

Product-friendly filtration through frequency-controlled booster pumps.

No filter aids necessary, no disposal of filter aids (Diatomite etc.).

Integrated CIP/SIP cleaning for optimum filtration results and hygiene. Hot sterilisation.

Intelligent process control for simple and safe operation. User-optimised.

Control integration in existing control rooms and interface communication as required.

AdHoc service via VPN router.

Each system is tailored and optimised to your specific needs.