Rotating CrossFlow BECA® Systems - Let´s take a walk

BECA® Dynamische CrossFlow - Retentate sampling

BECA® Dynamische CrossFlow - Permeate sampling

The superior technology for:

Pharmaceutical industry: e.g. Product separation, liquid filtration, micro / ultra / nanofiltration, ultrapure water filtration, plant extracts, etc.

Chemical industry: e.g. Product separation, liquid filtration, micro / ultra / nanofiltration, acid filtration, ultrapure water filtration, etc.

Drinks and breweries: product separation, beer recovery from yeast, beer filtration, beverage filtration, wine clarification, wine filtration, water filtration, vinegar filtration, spirits, etc.

Dairies: product separation, liquid filtration, thickening, etc.

General industry and production: product separation, liquid filtration, clarification filtration, liquid-solid separation process, concentration, etc.

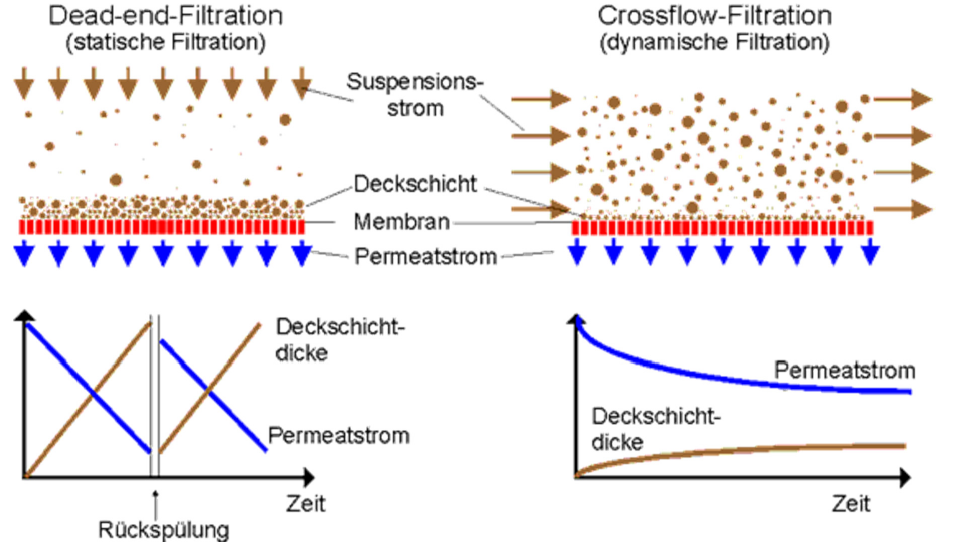

The BECA dynamic cross-flow technology for the separation of substances with sophisticated filtration properties without filter aids is the newest state of the art

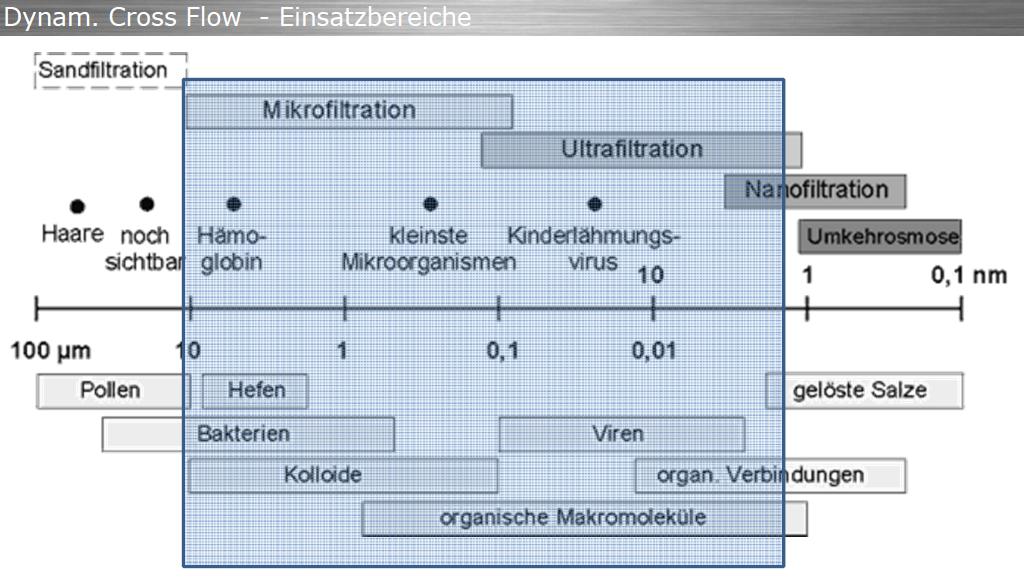

This dynamic cross-flow filtration, which can be modularized between 5 nm and 2000 nm, is ideally suited to meet all relevant quality requirements for safe, high-quality separation, filtration and recovery of valuable substances with the lowest operating costs and the highest product quality.

This sterile separation does not cause a negative change in the oxygen content, taste, etc. After this sterile filtration, the product can be used for further processing. The optional turbidity measurement and other quality measurements continuously determine the filtrate quality. Various measuring devices can be added inline as required.

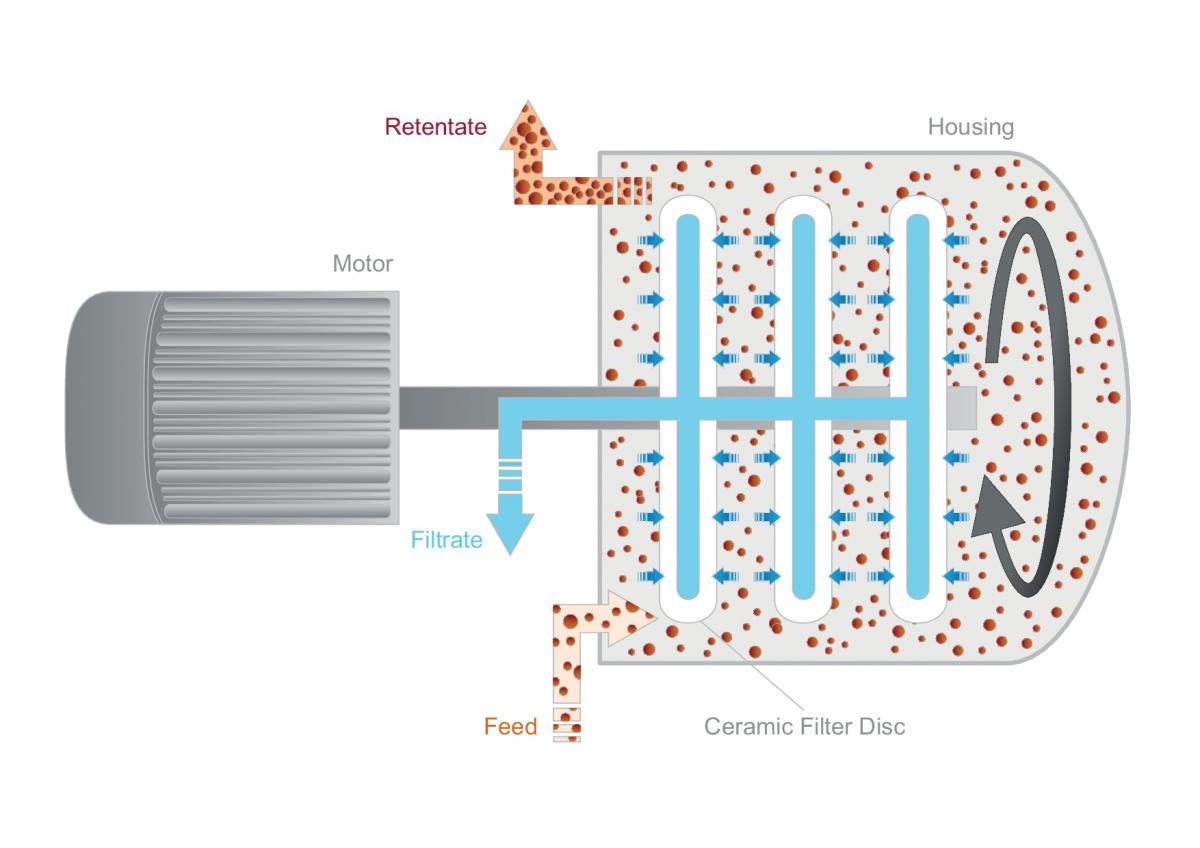

The BECA® dynamic cross-flow system technology filters and separates extremely gently, at very low pressure and low flow velocity, thereby preventing negative influences on the ingredients. The dynamic cross-flow system can concentrate the biomass highly; the efficiency and yield are advantageous.

One of the main reasons for this is the independent control and setting of the optimal transmembrane pressure and the counterflow speed.

The BECA® dynamic cross-flow system also shows its advantages in the very gentle treatment of the product. The increase in temperature is very small due to the low energy consumption.

The very low filter area power requirement of e.g. only approx. 0.1 to 0.2 kW / m² enables you to make additional substantial savings, very quick amortization and a high, additional profit. The energy savings can reach up to 80% compared to conventional cross-flow systems.